Preparation before Truck refrigeration unit installation

1. Unpack the box contents in your warehouse.

2. Check if the box content corresponds to the bill of material on the packaging.

Condenser Installation

1. Present the drilling template: take SF-600ES as an example.

2. Mark out fixing holes and the electrical harness and hoses hole.

3. Drill the fixing holes.

4. Drill the electrical harness and hoses hole.

5. Install the 4 silent blocks:

- put silicone to waterproof on the bottom.

- put silicone to waterproof on the 4 screws before to install the host unit.

6. Lift and install condenser: Align the mounting holes, put on the gasket, insert the bolts, and tighten them.

Evaporator Installation

1. Mark the fixing holes for the evaporator.

2. Drill the electrical harness and hoses hole inside the box.

3. Lift and install condenser: Align the mounting holes, put on the gasket, insert the bolts and tighten them.

Evaporator Installation

1. Mark the fixing holes for the evaporator.

2. Drill the electrical harness and hoses hole inside the box.

3. Lift and install condenser: Align the mounting holes, put on the gasket, insert the bolts and tighten them.

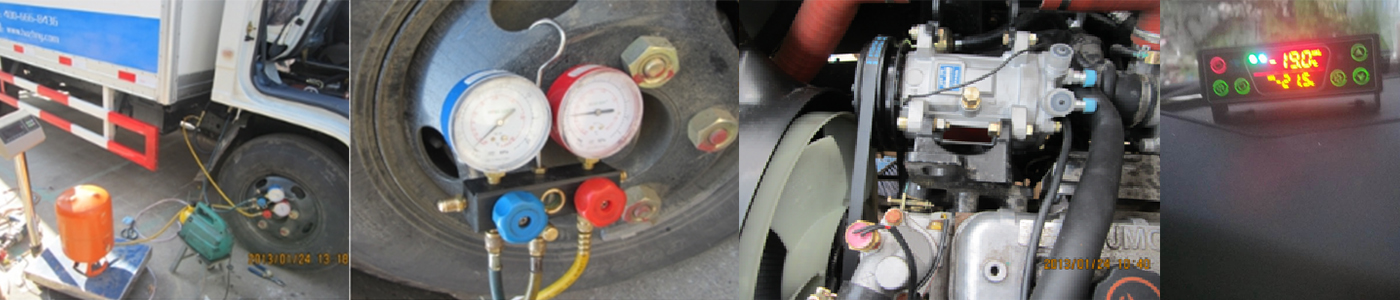

Compressor Installation

1. Attach the matching compressor bracket to the side of the engine.

2. Place the compressor on the installed support and tighten it with bolts.

3. Measure the length of belt required between engine wheel and compressor wheel, and match the triangle belt.

4. Adjust the tension rod to the nearest state between the compressor wheel and the engine wheel, install the triangle belt, and then adjust the tension rod to the belt tension state.

Connecting pipeline

Connect the pipeline between the evaporator, the condenser and the compressor, according to the principle of the truck refrigeration unit and the difference of the interface and aperture of each connecting hose.

Connect the pipeline between the evaporator, the condenser and the compressor, according to the principle of the truck refrigeration unit and the difference of the interface and aperture of each connecting hose.

| Attention: |

1, Connect the pipe correctly, and distinguish the high-pressure pipe and the defrosting pipe.

2, When connecting, the pipe connector must be inserted into place first, and then manually screwed until it cannot be screwed, and then tightened with a wrench. |

Vacuuming and Pressurizing

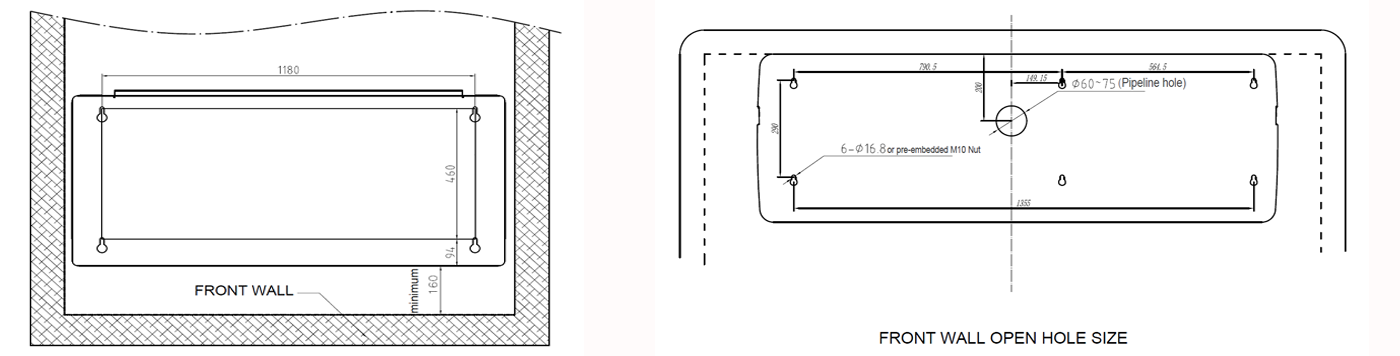

1, Check whether the vacuum pump can work normally, then check whether the pressure gauge is in good condition, and whether the pointer is zero.

.jpg)

2, Connect the red tube to the high pressure charging port, the blue tube to the low pressure charging port, the yellow tube to the suction port of the vacuum pump, and tighten the connectors.

3, Turn on the switch of the high and low pressure gauge, first vacuum for 10 minutes, and then close the high and low pressure valve of the pressure gauge, and observe whether the value of the pressure gauge will soon return to zero. If it returns to zero soon, it means that there is a large leak point, and it is necessary to remove the leak point and continue to vacuum, such as observing 10 seconds, the watch hand is negative pressure and does not move, you can continue to vacuum. Depending on the size of the unit, the vacuum time is 1.5 to 2 hours, and the pump of 4L/S is used as a reference.

4, After the high and low pressure valves on the pressure gauge are closed, keep the pressure for at least 1 hour, and the negative pressure does not rise, then the next step can be carried out.

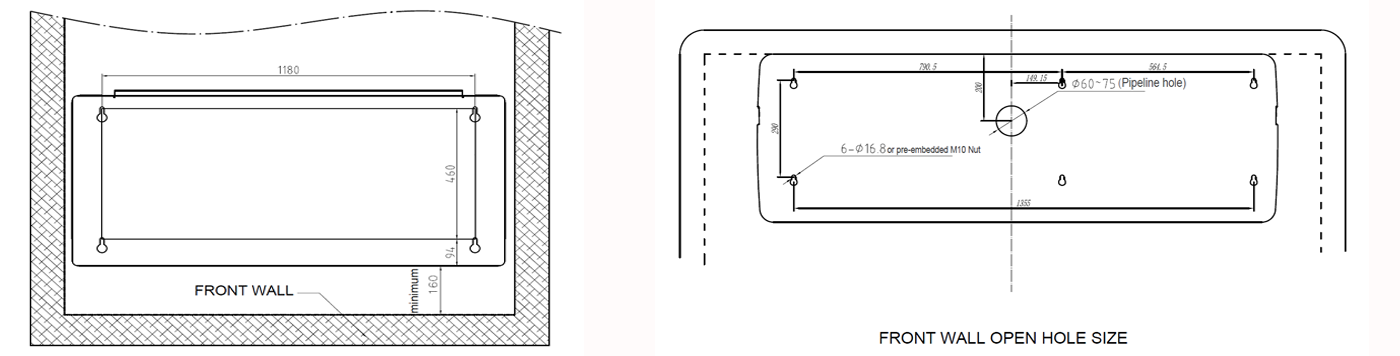

Connecting and Sealing

1, Connect theharness and hold the controller.

2, Use glue to seal.

Filling refrigerant

1, Close high and low pressure valves, and move the yellow pipe connector in the middle of the pressure gauge to the refrigerant tank outlet.

2, Expel all the air from the pressure gauge.

3, Open the refrigerant tank. Put the tank upside down on the electronic scale, open the high-pressure end of the pressure gauge, and begin to fill the refrigerant liquid in the high-pressure end until it is full.

4, Turn on the engine, turn on the unit switch after it is stable, and then turn on the low pressure switch of the pressure gauge, and start to charge refrigerant at the low pressure end until it is full.

This is the whole process of truck refrigeration units installation.

Once the truck refrigeration units installation process is complete, a trial and defrost test must be carried out. Please confirm that there are no issues before using it. If there is anything wrong, please contact us in time and Sinoclima will give you a good solution.

This is the whole process of truck refrigeration units installation.

Once the truck refrigeration units installation process is complete, a trial and defrost test must be carried out. Please confirm that there are no issues before using it. If there is anything wrong, please contact us in time and Sinoclima will give you a good solution.

.jpg)